printing, scan i 3D finishes for projects

of any size

3dBCfarm® and 3D technology for real projectsquality and consistency in each orderprofessional and detailed finishes

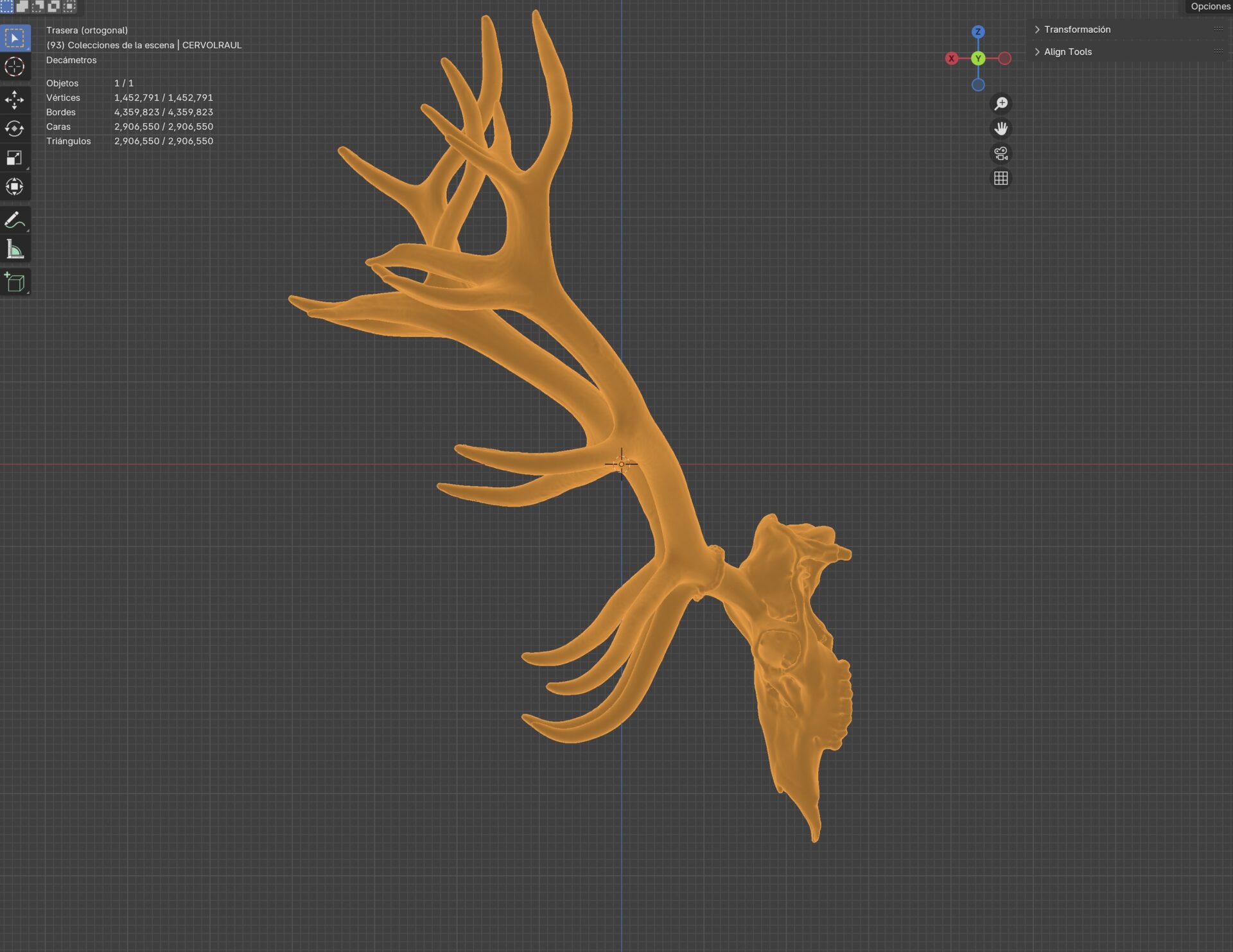

A 3dBCfarm® we turn digital files and objects into real parts with precision. We use printing FDM i SLA, 3D scan i manual finishes to achieve prototypes, models and replicas adapted to each customer.

We work for companies, institutions and individuals. Our system ensures that every step is documented and under control.

We advance step by step, without proclamations, demonstrating with results that rigor and service are the best guarantee.

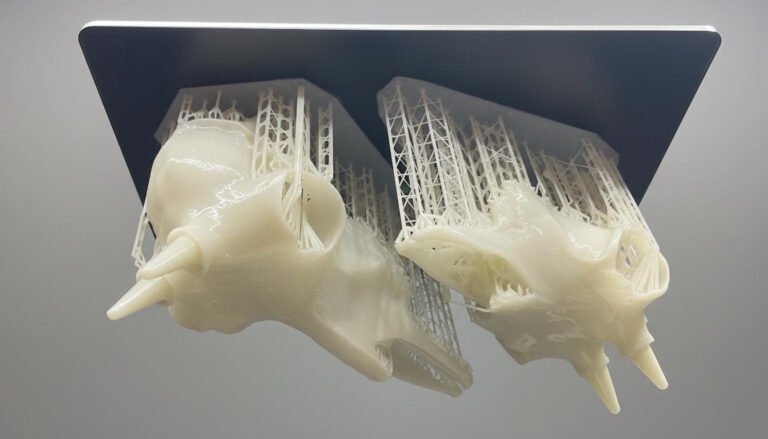

We create functional prototypes and validation mockups with FDM and SLA printing. We work with precision to ensure consistency in each piece.

We digitize objects with a high level of detail for reverse engineering, replicas, education or digital conservation. We turn real shapes into 3D models ready for analysis or manufacturing.

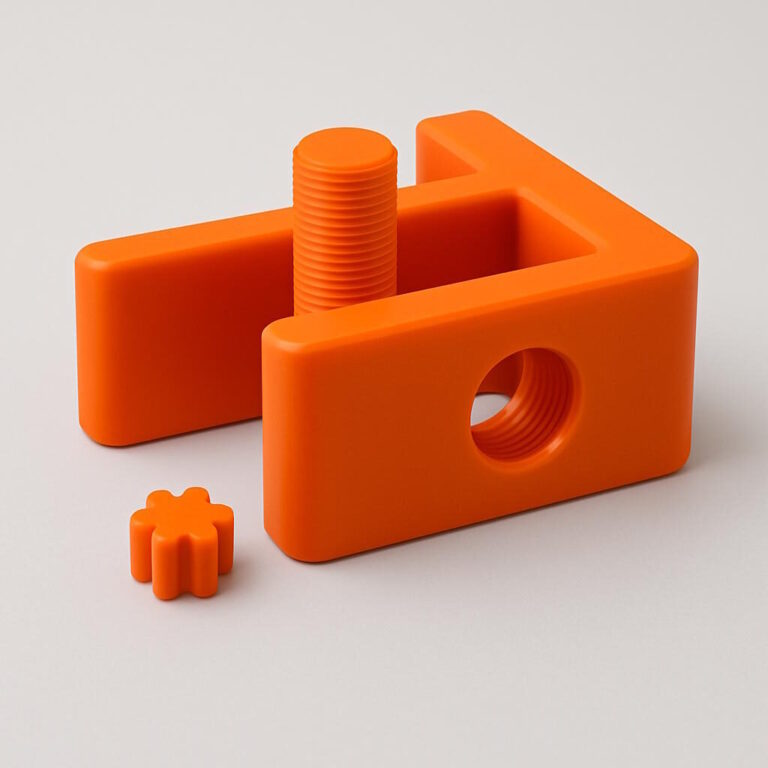

On-demand manufacturing in technical materials such as flexible TPU, polymers with carbon fiber and polycarbonate (PC). We also work with SLA resins for parts that require more detail. Solutions for prototypes and functional applications.

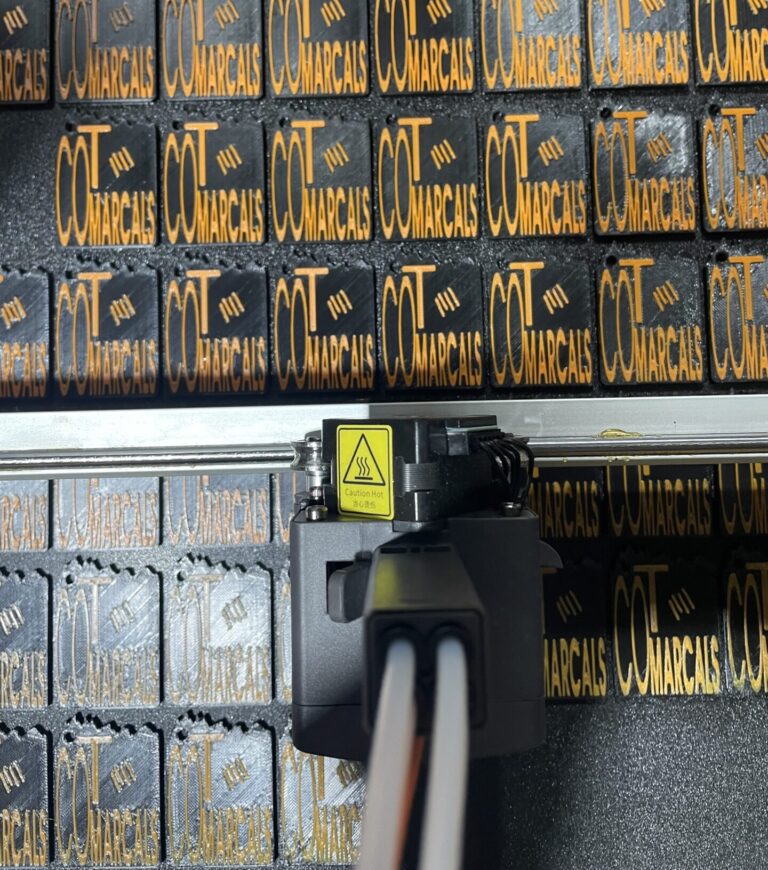

We produce short runs and final parts with stable quality, dimensional control and professional finishes. We guarantee full traceability.

3D: .STL, .OBJ, .3MF, .STEP/.STP, .PLY

Scan/Medicine: .DICOM, .NII/.RAW

Additional references: .PNG/.JPG for images,PDF with measurements

“Life is for the be brave!”

We are a equipment specialized in 3D printing and scanning. We work with a technical and methodical approach to guarantee reliable results in each assignment.

Our system ensures that the entire process - from reception to delivery - has complete traceability and rigorous control.

We define ourselves by clarity: let's explain what we do, how we do it and what each customer can expect. We do not work with promises, but with consistent results.

We offer services to companies, institutions and individuals, adapting to each project with the same exactness and precision.

SLA technology

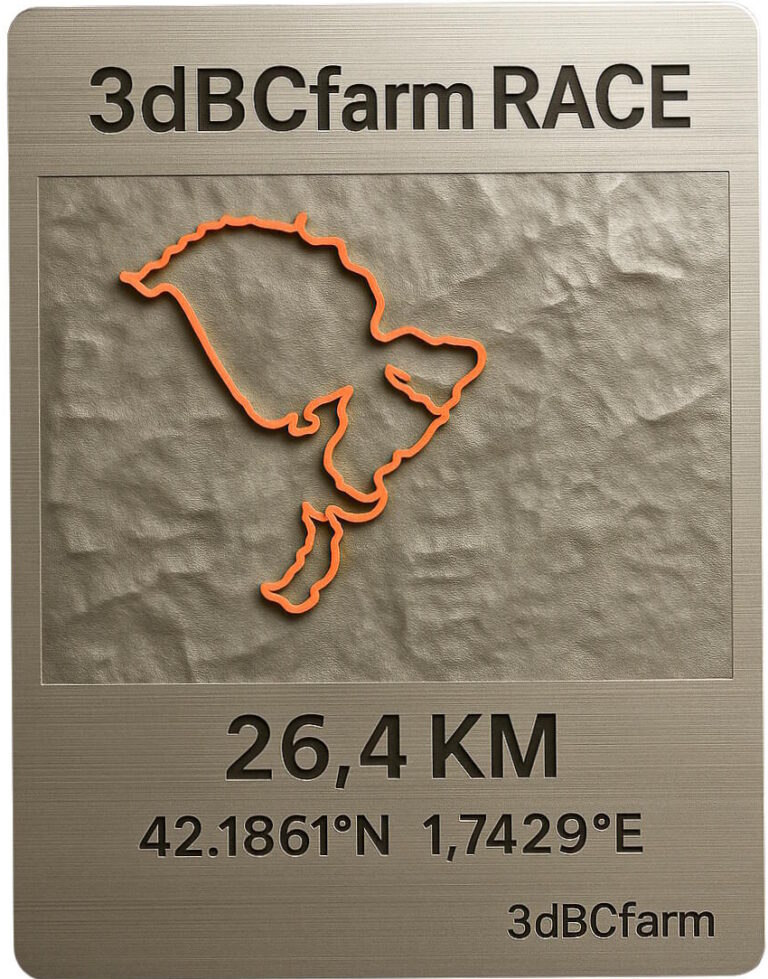

TOPOTrack transforms real geographic data (GPX, KML, coordinates or DEM) into one 3D printed physical topographic map.

SLA technology

PC Blend (FDM)

PLA bicolor (FDM)

PETG (FDM)

PETG bicolor (FDM)

We receive the file or object and check that it is viable. We only ask for the necessary information and leave the first details of the project recorded.

We analyze tolerances, sizes and end use. We define the most appropriate material, technology and level of finish. All configuration is documented to ensure traceability and consistency.

We produce the part with FDM or SLA technology, or digitize the object with a high level of detail according to the requested service. We monitor production to ensure quality and repeatability.

We apply manual finishes or professional paint when necessary, validate the result and deliver the piece with clear documentation. The project is closed with a complete record of the process.

Send us your file or project and we will guide you with a clear, traceable process adapted to your needs.

To provide the best experiences, we use technologies such as cookies to store and/or access device information. Giving consent to these technologies will allow us to process data such as browsing behavior or unique identifiers on this site. Withholding or withdrawing consent may negatively affect certain functionality and features.